Challenges:

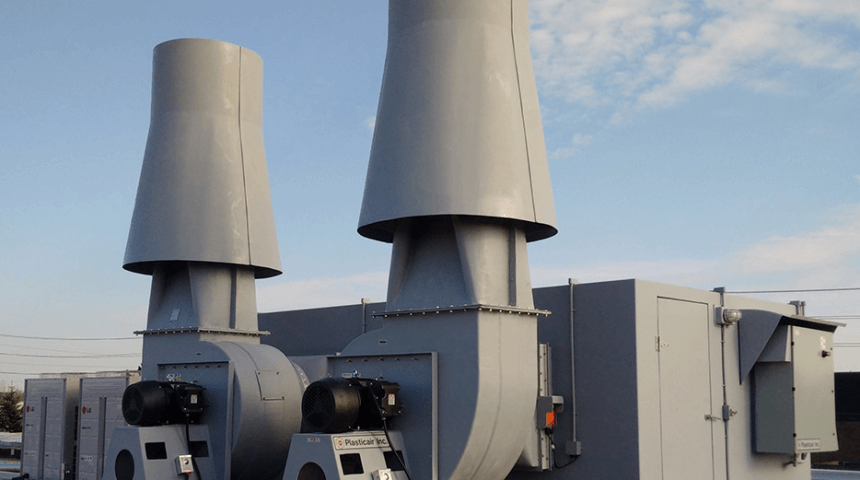

In this case, the original design incorporated a 7,000-cfm air handling unit with packaged gas heat, direct expansion (DX) cooling, and a sensible-only heat pipe energy recovery device. We knew there was a better solution that could improve efficiency and cut costs. (Check out our blog for details on different energy recovery technologies.)

The Solution:

Working with Bousquet, we designed a unit using an enthalpy wheel for total latent and sensible energy recovery. With the correct energy recovery technology, we realized a number of efficiencies, specifically:

- Reduced the size of integral humidifier capacity by 100 lbs/hr

- Reduced cooling by 82 MBH (>6 tons)

- Reduced heating by 350 MBH

Our Approach:

We collaborated closely with Nagas to design an optimal energy recovery solution. Our approach involved thorough analysis and integration of advanced technologies to enhance performance. We engaged in continuous communication with all stakeholders to ensure the revised design met everyone’s expectations.

Conclusion:

The owners approved the revised design, resulting in initial capital cost savings and future energy savings. This project is a great example of a complete team of professionals—including general contractor, mechanical contractor, and sales engineer—all working together to deliver value to the building owner.