The Canadian Centre for Inland Waters (CCIW) is an Environment Canada building located in Burlington, Ontario. The CCIW staff conducts environmental research aimed at better understanding and predicting the effects of contaminants and other substances on our water systems, playing a major role in the management of the Great Lakes and other water ecosystems.

In late 2015, Mattina Mechanical began construction in the facility, rejuvenating outdated mechanical systems and installing new ones for repurposed areas.

Challenges

Since this was an existing building with current employees working, there were many time and space restrictions that needed to be addressed.

The main air handling unit (AHU), which required a fan upgrade, was located in the building’s mechanical room. The existing supply and return fans were too large for a direct replacement to fit through its double doors, necessitating an alternative fan selection.

Additionally, the building had inadequate humidification, leading to very dry rooms during the winter months. This not only affected lab procedures but also posed potential health risks if rooms did not maintain a minimum relative humidity of 35%.

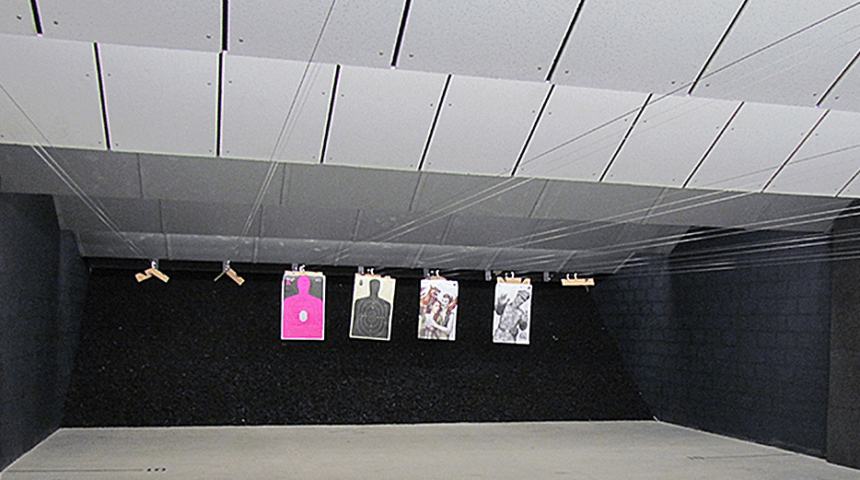

Another challenge was that the existing fume hoods each had dedicated exhaust fans located in the mechanical room. These fans were inefficient, needed replacement, occupied a lot of space, and lacked redundancy; a failure of just one fan could result in downtime for lab technicians working under that fume hood.

The Solution

By leveraging our extensive product offerings, we developed tailored solutions to address each of the project’s challenges.

The AHU replacement fans needed to be compact while delivering large quantities of air at high static pressure. We chose PennBarry’s plenum array fans, which provided 73,000 cubic feet per minute at 6.0 inch water gauge using just five fans arranged in a pyramid-like structure. The largest dimension of these fans was 48 inches, allowing them to fit easily through the available door.

To combat low relative humidity, we retrofitted new humidifiers into the existing AHUs. The Nortec line of SETC steam exchange humidifiers utilized plant steam to generate clean atmospheric steam through stainless steel heat exchangers. Where plant steam was unavailable, we deployed a Model GS gas-fired humidifier, featuring Nortec’s high-efficiency condensing technology, providing over 10% better efficiency than competitors while allowing for more cost-effective CPVC venting instead of expensive stainless steel.

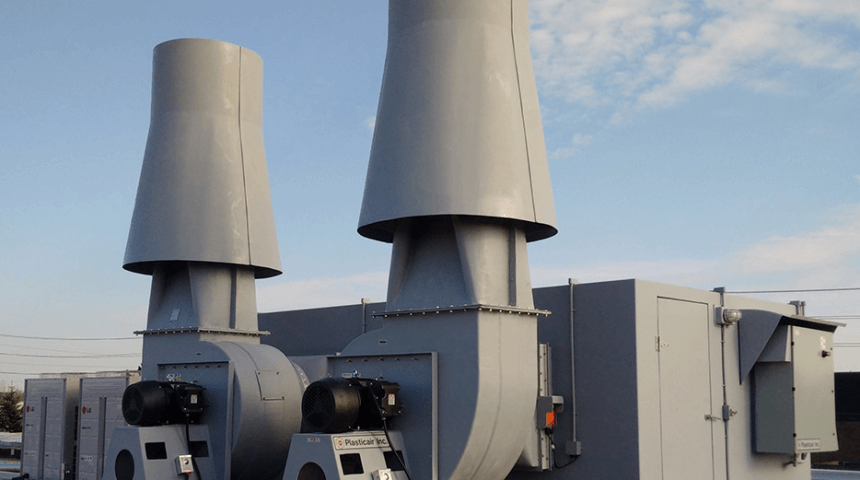

For the fume hoods, we implemented Plasticair’s SKYPLUME system, addressing the concerns associated with older exhaust fans. The FRP construction ensured longevity due to its resistance to corrosive lab chemicals, and high-velocity dilution exhaust nozzles ensured safe extraction of fumes. The three-exhaust stack arrangement provided 100% redundancy and potential for increased exhaust rates for future building expansions. A run-around glycol loop was installed in the inlet plenum of the fan for heat recovery, which was routed back to the building’s main AHU, further opening up space in the mechanical room by eliminating the twenty-two existing fume hood fans.

Our Approach

Our approach focused on collaboration with Mattina Mechanical to ensure seamless integration of the new systems while minimizing disruption to ongoing research activities. By prioritizing efficiency and accessibility, we delivered solutions tailored to the unique needs of the CCIW.