I’m always surprised how difficult it is to get new technologies to take hold in a market. I’ve been representing LG variable refrigerant flow (VRF) for over 10 years and the technology is still only scraping the surface of its possible impact on the HVAC market in Canada. Through the years, I’ve discussed VRF with several engineers, owners, and contractors and the question, mostly, haven’t changed. It’s a bit like groundhog day. The good news is that I’m getting much better a providing succinct responses. Like watching Bill Murray play the piano!

The following are common questions or misconceptions about the technology …

1. VRF is great but it’s so expensive?

Nothing could be further from the truth! In a recent project, I worked closely with a developer to compare heat recovery VRF to a 2-pipe fan coil system. The VRF solution was within a couple percentage points of the antiquated 2-pipe solution. It was an easy decision to make the switch to VRF and leave the occupant comfort complaints in the past. I have also costed out projects with 4-pipe fan coil units, hybrid heat pump and heat pump solutions, which all proved to be more expensive than VRF.

– VRF systems present a cost-effective proposition through their ability to optimize energy consumption, leading to reduced operational costs over the system’s lifecycle.

– The modular design of VRF allows for phased installation, aligning with project budgets and cash flow requirements.

2. What do you use for supplementary heat?

NOTHING! If you ‘re in a moderate climate like Southern Ontario there is ZERO need to provide supplementary heat. It’s just a waste of money! The O’Dell offices have operated on VRF alone since 2013.

VRF systems are rated to operated to -23oF in heating mode. The ASHRAE 99.6% design day in Toronto is -3oF. You’ve got heat to spare even on the coldest days of winter.

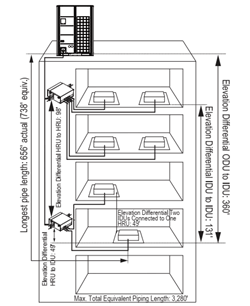

4. I’m building a 30-storey building, its too tall for VRF.

Big and small, VRF can cover them all! You’re not even stretching the system capabilities with a 30-storey building. VRF systems have incredibly flexible refrigerant piping capabilities. LG can have an elevation distance of 360-ft between the outdoor unit (ODU) and indoor unit (IDU – fan coil) and you can run up to 3,280-ft of equivalent pipe length.

Here’s a cool case study of a 42-storey VRF project in Burnaby, BC

4. Doesn’t VRF performance really suffer in the cold temperatures?

There is a degradation of heat output as ambient temperatures get colder. But, it’s not as severe as most people think. I took average performance of all the LG single chassis ODU’s (6-20 tons) and plotted heat output vs. ambient. The heat output doesn’t start to degrade until 9oF (-12.8oC)! Looking at the 99.6% design day, the heat output is still >80% of rated capacity. So, no need to worry about heat.