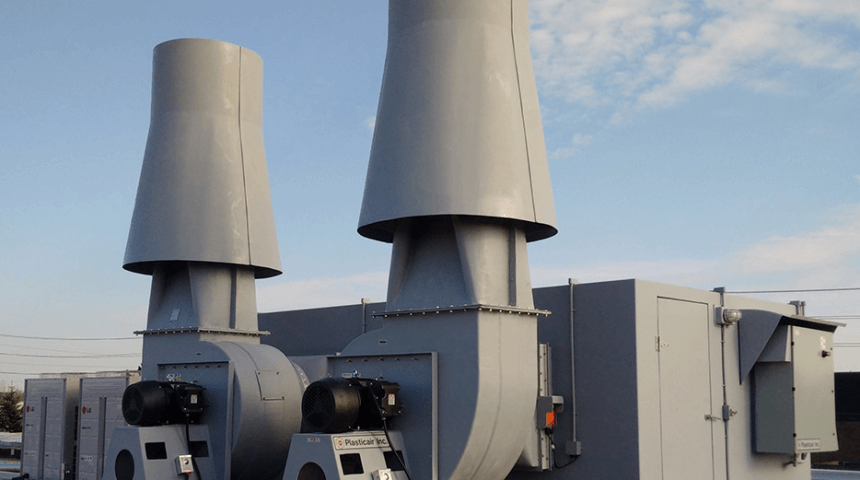

Dectron Dry Coolers

Dectron has been manufacturing Dry Coolers for many years to deliver reliable heat rejection for their industry leading Dry-o-tron natatorium dehumidifiers. The have now made their Dry Cooler Technology available as a standalone product.

Why Dry Coolers?

Dectron’s Dry Cooler technology is ideal for any application where medium to large-scale fluid-cooled heat rejection is desired. The design is unique and provides many advantages over traditional Dry Coolers:

- V-bank fin-and-tube coil design minimizes unit footprint while maximizing the surface area used for heat rejection. The result is more capacity in less space compared to standard slab coil designs. It’s also a less bulky unit for your contractor to rig and lift.

- Variable-speed EC motor fans standard. Highly efficient and very low-maintenance motor varies its speed to control fluid temperature with precision.

- Superior corrosion protection: coils are fully-dipped in a state-of-the-art coating (3,000-hour salt spray rating)

- Special coating keeps dirt from building up the coil surface and interfering with heat transfer

- Coating is also UV-protected and resistant to acidic humidity (30 Cycles, 0.2 SO2).

Options

- Unit-mounted pump kits are available for a true heat rejection package. For large Dry Coolers, each two-fan row is equipped with its own pump kit for redundancy and reliability.

- Factory-provided aquastat to control fan speed based off leaving fluid temperature.

Applications

- Dry Coolers are perfect for a variety of fluid-cooled heat rejection purposes, including:

- Data Centers — where full cooling is needed even during low ambient conditions.

- Waterside economizer on chillers.

- Geothermal heat pumps or wells needing supplementary or emergency heat rejection

- Any fluid cooled A/C application.

Consider packaging Dry Coolers with a chiller to offer free cooling capability. It improves the efficiency of the system and may be required to comply with ASHRAE Standard 90.1 depending on your climate zone.

ASHRAE 90.1 Requirements for Economizer

| Climate Zone | Min. Cooling Capacity |

| 1a, 1b, 2a, 3a and 4a | Economizer not required |

| 2b, 5a, 6a, 7 and 8 | Required if ≥135 MBH |

| 3b, 3c, 4b, 4c, 5b, 5c and 6b | Required if ≥65 MBH |

As the table shows, most climate zones have a requirement for economizer on big systems. Waterside economizer, also called free cooling, works by allowing the dry coolers to lower or supplant compressor runtime by taking advantage of low-ambient conditions to provide significantly chilled water to the loop.

If you’re in Southern Ontario, chances are your sitting in climate zone 5A or 6A, so any load greater than 135MBH requires an economizer solution.