In the commercial HVAC world, we typically run into two (2) separate options when it comes to fan motor selections. These are belt drive and direct drive motors. Within the direct drive options we can also split this category up into PSC and electronical commutated motors (ECM). Here is a summary of these options and both the advantages and disadvantages that come with them.

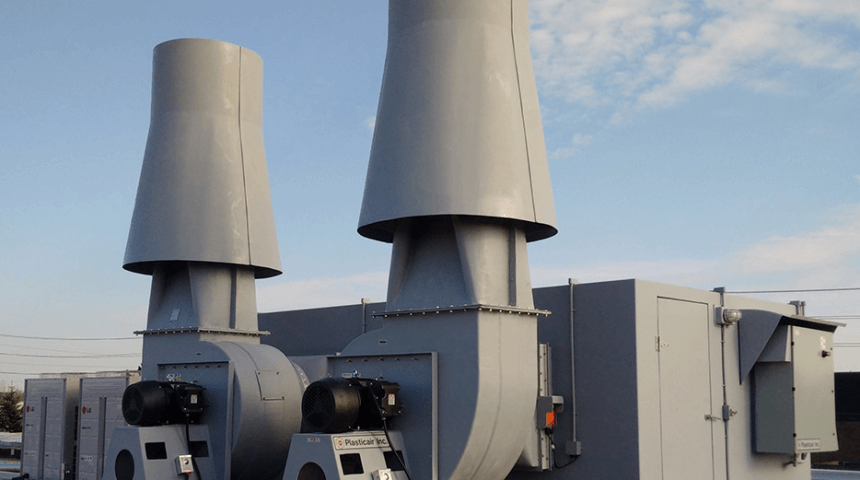

Belt Driven Motors

A belt driven motor is one that uses two (2) separate shaft/pulleys systems with a belt connecting the two of them to operate. The fan motor shaft creates the initial torque which is then transferred to the secondary shaft which turns the fans wheel/propeller to create the airflow

A belt driven motor is one that uses two (2) separate shaft/pulleys systems with a belt connecting the two of them to operate. The fan motor shaft creates the initial torque which is then transferred to the secondary shaft which turns the fans wheel/propeller to create the airflow

Advantages

- Easy to vary speeds by changing out belts and pulleys

- Readily available in different horse power and voltages

- Larger airflow capacities

- Typically easier to change out motor

- Most manufacturers are easily interchangeable for replacement

Disadvantages

- More maintenance

- Motor runs at full rpm if a VFD is not used

- System energy losses through belt and pulley system

- No fractional horse power options

- Heavier at smaller horse powers

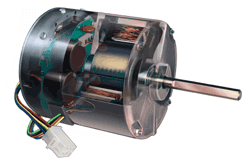

Direct Drive Motors

Simply put, the motor is connected directly to the shaft of the wheel/propeller which minimizes system efficiency losses

Simply put, the motor is connected directly to the shaft of the wheel/propeller which minimizes system efficiency losses

PSC motors

A Permanent Split Capacitor (PSC) motor is a type of AC motor that has two windings (run and start) with a capacitor connect in the circuit. When the motor is running, the two windings remain in the circuit the entire time (hence permanent)

Advantages

- Low costs

- Simple on/off use

- Come in fractional horse power

- Less maintenance than belt driven motors

Disadvantages

- Less efficient the ECM

- Once selected, can only run at one speed

- Noisy as they always run at full speed

- No programmable controls

- Hard start which add stress on blower wheels

ECM

An electronically commutated motor (ECM) is a brushless DC motor that utilizes electronic signals to control it’s speed and torque.

Advantages

- High efficiency

- Can modulate the controls to vary speed without VFD

- Programmable

- Low noise output

- Low maintenance

- Fast response to controls

Disadvantages

- Higher cost than PSC motors

- Limited capacities as larger horse powers not yet available

- Not readily available for 575V Canadian marker

- More complex so harder to repair if needed