This post reviews the thermodynamic processes employed to humidify a space effectively. Regardless of the market, vertical humidification is delivered through either an isothermal or adiabatic process.

Isothermal Humidification

Neptronic SKE

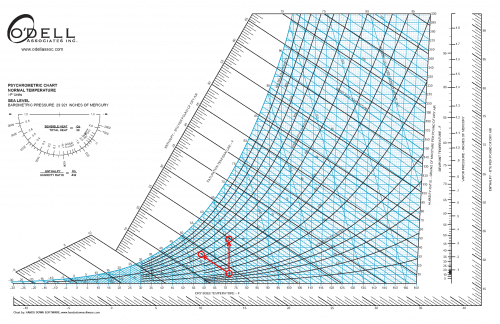

Isothermal humidification can be described as the process of adding moisture to an airstream without affecting the dry bulb temperature (Diagram 1: Process 1 à2). This is achieved by injecting steam into the airstream. The steam is generated with either an electric resistance or a gas heat exchanger to boil water. It takes 1,000-btu of energy to deliver 1-lb of humidification, effectively the energy required to change the state of water from liquid to gas. The steam produced is injected into the airstream to effectively increase its relative humidity without impact to dry bulb temperature.

Isothermal humidification is a widely adopted technology in the HVAC industry. It offers advantages of both precision and hygiene. Commercial humidifiers employ advanced logic to control the steam production from their equipment, making it possible to maintain humidity setpoints within a deadband of +/-1%RH. This can be critical in sensitive environments. Since isothermal humidification distributes steam, hygiene is an inherent benefit. Any particulate in the water is left within the boiling chamber, which can be flushed with drain cycles. The steam produced is pure, clean vapour.

Adiabatic Humidification

Neptronic SKH

Adiabatic humidifiers use the process airstream to evaporate water. On the psychrometric chart this process follows the line of constant web bulb temperature (Diagram 1: Process 1 à 3). It still takes 1,000-btu of energy to produce 1-lb of humidity, so you will note the reduction in dry bulb temperature. In many applications, this temperature depression can be beneficial. The technologies that employ adiabatic humidification include evaporative media, high pressure fogging & ultrasonic. These technologies can be employed in both in-space and ducted applications.

Neptronic SKV

Employing adiabatic humidification has multiple benefits beyond improved indoor air quality. The application of adiabatic humidification is gaining popularity due to its potential energy-saving opportunities. The cooling effect is often beneficial in offsetting internal heat gains from people, computers, and machinery. When coordinated with free cooling strategies, adiabatic humidification can postpone when DX refrigeration systems need to be enabled, mitigating peak demand charges. Engineers are also seeing the benefits of adiabatic humidification to deliver cooling as an opportunity to positively impact decarbonization efforts. These benefits are not reserved for hot climates, offering significant value in the Ontario, Canada environment.

Diagram 1