Temperature stratification in a warehouse refers to the variation in temperature within the enclosed storage space. This phenomenon occurs when the warm air rises to the upper levels of the warehouse while cooler air settles near the floor. Several factors contribute to temperature stratification in such settings, including heating and cooling systems, insulation, and the presence of stored goods.

Warehouse temperature stratification can result in significant temperature differences between the top and bottom of the facility, impacting worker comfort & productivity, operation of heating and cooling systems and the condition of stored products. Proper ventilation, insulation, and well-designed heating or cooling systems are essential for minimizing temperature differentials and maintaining a consistent temperature throughout the warehouse.

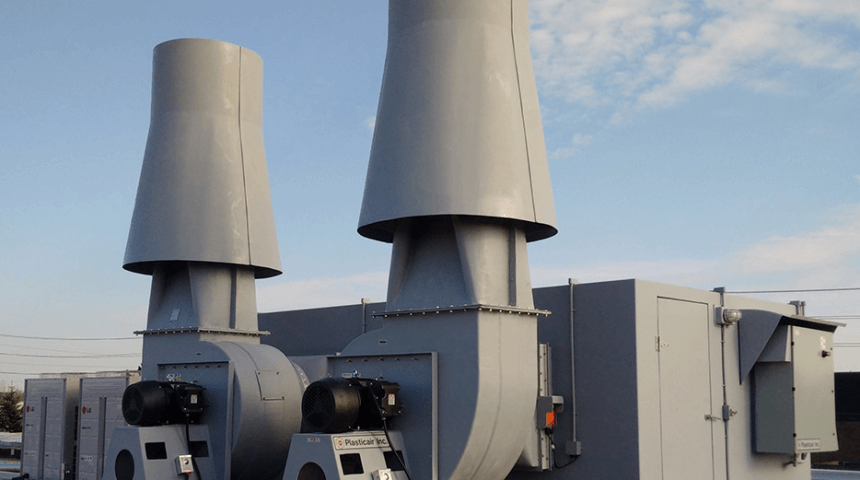

Destratification is a technique used to improve the air quality and temperature distribution within a large enclosed space such as a warehouse. It involves the process of mixing the air to eliminate significant temperature differences. This process is most effectively achieved using HVLS (high velocity, low speed) destratification fans or HTHV (high temperature, high velocity) Heating Units.

Benefits of Destratification in Warehouses

- Improved Energy Efficiency

- By redistributing the warm air from the ceiling back down to floor level, destratification reduces the need for additional heating during colder months. Buildings without a destratification strategy may experience upwards of a 35% increase in heating energy required in winter months. This means warehouses can maintain a more consistent and comfortable temperature without overworking heating systems.

- Enhanced Comfort for Workers

- A comfortable working environment is crucial for warehouse staff. Destratification improves comfort by eliminating hot and cold spots, creating a more consistent temperature throughout the space. Workers are less likely to experience discomfort from temperature extremes, which can lead to increased productivity and reduced absenteeism. Destratification equipment can provide a significant reduction in temperature differential (typically about 2-3C between floor and ceiling) – resulting in a much more comfortable work environment.

- Enhanced Productivity

- Improved comfort levels translate into higher worker productivity. Staff who aren’t distracted by temperature fluctuations can focus on their tasks more effectively. Furthermore, when the air is evenly distributed, it reduces the likelihood of fatigue, which can improve worker concentration and performance.

Overall, destratification is a highly valuable technique when considering optimizing warehouse operations. By enhancing energy efficiency, reducing operating costs, increasing worker comfort and productivity, it brings a multitude of benefits. Implementing a destratification system is an investment in a warehouse’s long-term success, and it is well worth the effort to create a more efficient and comfortable workspace for both employees and products.

Cambridge Air Solutions, a key manufacturing partner of ours, stands out as industry leaders in High Temperature Heating & Ventilation (HTHV). Their HTHV products have been proven through both the DOE study and their own building studies to save between 20% to 70% on energy, depending on the building, location, application, and installation. This shows that HTHV heaters are the most energy efficient space heaters on the market. Contact your local O’Dell office to learn more.