The Conestoga Meat Packers (CMP) plant in Breslau, Ontario, provides premium pork products. Their main processing plant underwent a significant expansion throughout 2017 and 2018. Mallot Creek provided engineering services, while Conestogo Mechanical completed the mechanical installation.

Challenges

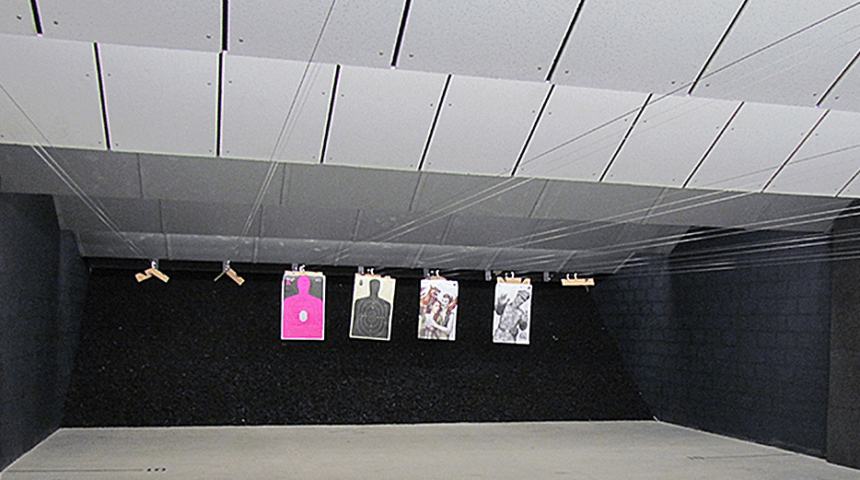

To meet the intense hot water demands of the facility, a QuikWater MegaHeater 8.3 was selected. This direct-contact water heating system is unique in its ability to produce pure, potable hot water up to 200°F. However, the configuration of the QuikWater MegaHeater required special attention to venting, as the process water is susceptible to anything in the vent system. The venting system needed to:

- Have smooth interior surfaces to eliminate the opportunity for bacterial growth,

- Be built in a manner that facilitates access to the MegaHeater, and

- Allow for cleaning of the vent system as necessary.

The Solution

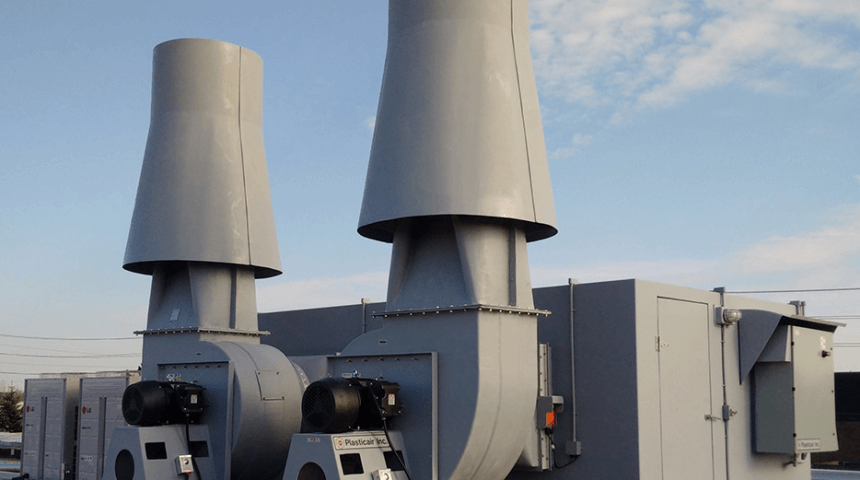

The Mallot Creek design called for a fully welded 28-inch diameter vent stack. Initially, we proposed a standard Ampco Model N series vent solution, which is installed with a sealant and ring clamp system. While this solution facilitated installation, the large number of joints posed a potential risk for bacterial growth.

Working with Conestoga Mechanical and Ampco, we proposed a compromise: constructing the complete vent stack in three welded sections. This approach reduced the number of joints to two, addressing both access and cleaning requirements. After verifying site measurements, we generated final drawings and calculated the vent stack pressure drop to ensure compatibility with QuikWater requirements.

Our Approach

We collaborated closely with Conestoga Mechanical and Ampco to develop a solution that met all the specified requirements. Our team conducted thorough site measurements and calculations to ensure the vent stack design was both efficient and effective. By reducing the number of joints and ensuring easy access and cleanability, we delivered a robust and hygienic solution.