Dordan Mechanical was tasked with the base building work for a new wing at Loyalist College in Belleville, Ontario. With our extensive ventilation offerings and HVAC system expertise, we were approached to deliver a cost-effective solution for the laboratories that would provide a safe working environment for both students and instructors.

Challenges

The classroom spaces were designed to accommodate fully operational laboratories, which required effective ventilation for numerous laboratory hoods and point-source extraction systems.

The Solution

We offered an uncompromising and economical solution to maintain a safe working environment for Loyalist College’s new laboratory facilities.

The lab hoods were installed in two main classrooms: Wet Lab 1, featuring six hoods, and Wet Lab 2, with four hoods. Each hood was designed to operate at two different exhaust levels depending on the sash height, necessitating a variable exhaust airflow solution for both hoods and classrooms.

To control airflow from each hood, we utilized Krueger model RVE 316 stainless steel terminal units, each equipped with a stainless steel airflow sensor. The terminal unit’s core comprises a Belimo VFP-600 airflow sensor, a VRP-M controller, and a fast-acting, 2-second stroke LMQ24-MFT actuator. This complete Belimo package is easily commissioned and customized on-site using user-friendly software.

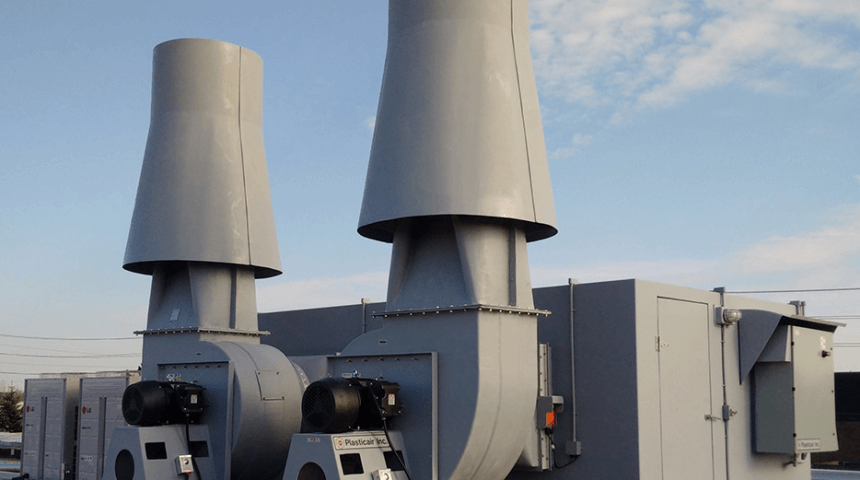

Exhaust for the lab hoods was managed by dedicated PennBarry FH exhaust fans in each classroom, complete with a bypass plenum to allow for variable exhaust airflow while maintaining an acceptable discharge plume height. The dampers on the bypass plenum were controlled by a Honeywell controller, along with a Greystone static-pressure sensor located in the main exhaust duct.

In addition to lab hood ventilation, we installed four separate desktop ventilation systems across various classrooms. These systems, provided by Plymovent, consisted of four, six, twelve, and thirteen fume arms, respectively, along with pressure controls similar to those used for the lab hoods and VFD-driven direct-drive exhaust fans.

Each user workstation was equipped with a MINIMAN-75, 3-inch exhaust arm complete with an isolation damper. When in use, students could open the damper to ensure adequate ventilation over their experiments.

As dampers throughout the system opened and closed, the static pressure in the main exhaust duct for the classroom fluctuated. Similar to the controls for the lab hoods, this pressure was monitored, and the exhaust airflow was modulated via a VFD to maintain a preset value

Our Approach

Our approach involved close collaboration with Dordan Mechanical to ensure that the ventilation systems met the unique requirements of the new laboratory spaces while remaining cost-effective. We focused on optimizing airflow and safety to create an ideal learning environment.