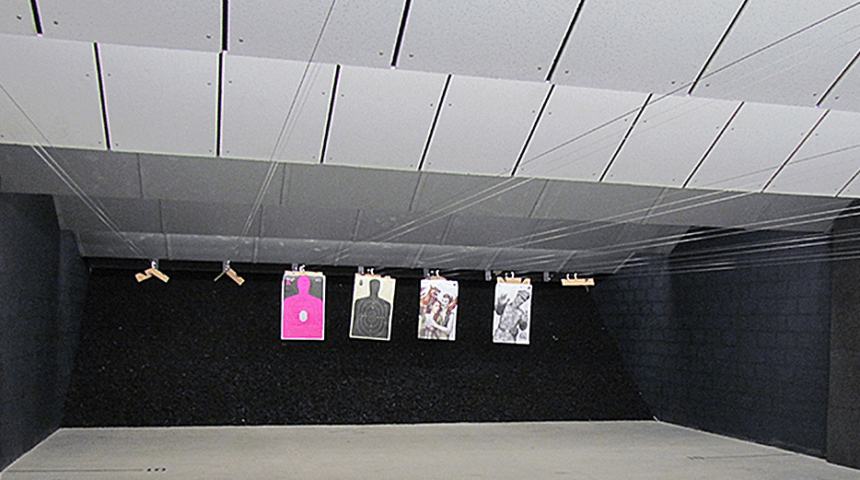

Rapid Novor recently settled into Kitchener’s Catalyst137 facility, requiring a lab hood designed to efficiently remove contaminants associated with their research processes. After selecting a hood, the owner reached out to M.A. Bryan (MAB) Engineering for comprehensive HVAC design. To determine the best exhaust fan solution for the hood, MAB enlisted our support.

Challenges

Upon reviewing the list of chemicals to be used under the hood, it became clear that selecting the appropriate materials for the fan and associated ductwork was crucial. We determined that fiberglass reinforced plastic (FRP) was the most suitable option, given its outstanding reliability, durability, and longevity when handling processes involving acids, alkalines, sulfides, chlorides, and solvents.

The Solution

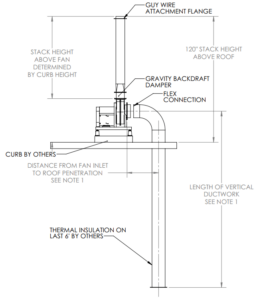

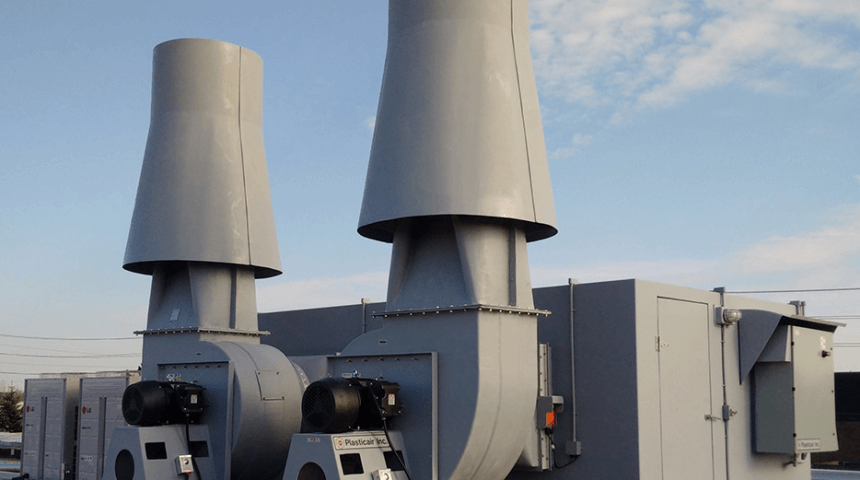

We identified Plasticair’s FRP BCMPA as the optimal fan selection to complement the lab hood. This fan featured an FRP stack designed to efficiently expel chemical fumes away from the building. Its construction included a backward inclined wheel made of FRP, along with a Teflon seal and shaft sleeve, and a carbon steel shaft wrapped in an FRP sleeve, all contributing to the fan’s extended lifespan. To further ensure safety, Plasticair also fabricated FRP ductwork to protect against potential chemical fumes in the airstream.

Our Approach

Understanding that the installation of FRP ductwork isn’t routine for every contractor, we collaborated closely with Plasticair to provide detailed installation support. Our collective efforts ensured a seamless and successful installation process.