The University of Guelph required a corrosion-resistant exhaust fan for their labs in the Food Innovation Center. They also needed the exhaust to be released at a height sufficient to prevent contaminant spread to nearby buildings and aimed to recover energy leaving the building.

Challenges

We faced several challenges in designing this system. We needed an exhaust system capable of withstanding corrosive lab environments, preventing the spread of contaminants, and incorporating energy recovery. Additionally, the system had to expel exhaust at a high enough altitude to avoid contaminating nearby buildings while efficiently recovering energy without cross-contamination.

The Solution

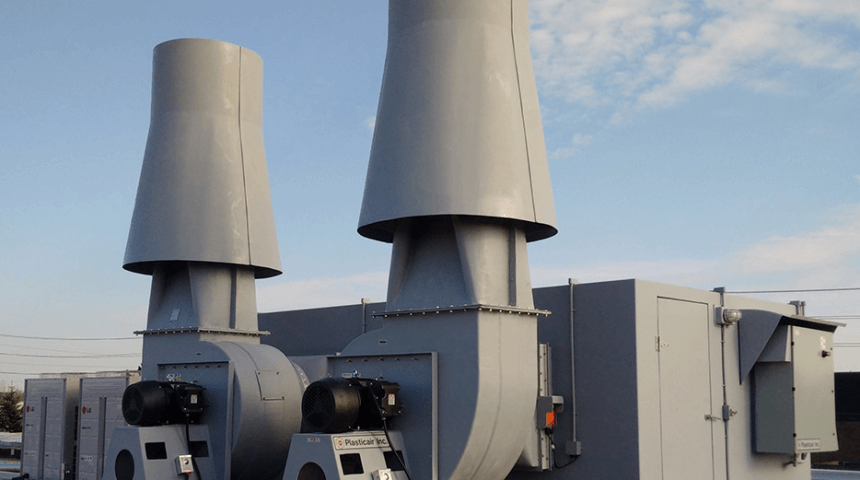

Working with Plasticair and mcCallum Sather, we developed a custom-designed solution that met all the project’s requirements. Our chosen solution was a fiberglass reinforced plastic (FRP) lab exhaust system from Plasticair, featuring:

- Full FRP Construction: Including a UV stabilizer for enhanced durability.

- Double Wall, Insulated Plenum: With stainless steel access doors for easy maintenance.

- DMF-270 Bifurcated, Direct Drive Exhaust Fans: Dual fan configuration for full redundancy, ensuring continuous operation.

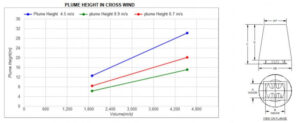

- SKYPLUME Induction Air Nozzle: To generate a high plume exhaust, ensuring contaminants are dispersed safely.

- Discharge Air Sound Attenuators: To minimize noise pollution.

- Integral Heat Recovery Coil: To recover exhaust energy with zero cross-contamination, enhancing energy efficiency.

- Lifetime Warranty Against Rust: Ensuring long-term reliability and performance.

Our Approach

We worked closely with Plasticair and mcCallum Sather to understand the specific needs and challenges of the University of Guelph’s Food Innovation Center labs. Our approach focused on designing a robust, corrosion-resistant exhaust system that met the stringent requirements for contaminant dispersion and energy recovery. By utilizing advanced materials and technologies, we ensured the system would provide reliable, long-term performance.